|

Oriental Casting and Forging Limited

|

forged grinding ball and cast grinding ball

| Price: | 690.0~780.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.Sizes:DIA20-150mm

2.Hardness: HRC55-67

3.Chemical elements:C . Si . Mn . P . S . Cr

4.Impact toughness: >12J/CM2

5.Endurance impact test: >12000

Forged Grinding Ball and Cast Grinding Ball:

Introduction of the products:

Specification:

1.Hardness:HRC55-67

2.Impact toughness:>12J/CM2

3.Diameter:20mm-150mm

4.Endurance impact test:>10000

5.Diameter: 20mm-150mm

Characteristics: .High hardness .Good wear resistance .Good even wear .Even wearing

Application fields:

.Mines .Cement plants . Power station .Chemical industry

Packing:

1000KG bags or steel drums(850-900kgs)

Chemical Elements:

| name | C | Si | Mn | P | S | Cr | HRC |

| 60Mn | 0.55-0.65 | 0.17-0.37 | 0.7-1.0 | <0.04 | <0.04 | <0.25 | 52-60 |

| 65Mn | 0.62-0.70 | 0.17-0.37 | 0.9-1.2 | ≤0.035 | ≤0.035 | ≤0.25 | 56-63 |

| 75Mn | 0.72-0.92 | 0.17-0.37 | 0.7-1.0 | <0.04 | <0.04 | 0.4-0.6 | 58-64 |

| 60Si2CrV | 0.56-0.64 | 1.4-1.8 | 0.4-0.7 | ≤0.03 | ≤0.03 | 0.9-1.2 | ≥60 |

Specification and Hardness of Forged Grinding Ball

Nominal diameter (mm-inches) | Diameteical tolerance (mm) | Weight of Single of forging ball in average | Number of piece of One ton forging ball in average |

20-0.8" 25-1.0" 30-1.2" 40-1.6" 50-2.0" |

+2 -1 | 32 64 110 263 513 | 31250 15625 9090 3802 1949 |

60-2.4" 70-2.8" 80-3.2" 90-3.6" 100-4.0" |

+3 -2 | 888 1410 2104 2996 4110 | 1126 709 475 333 243 |

110-4.4" 120-4.8" 130-5.2" | +4 -2 | 5457 7102 9030 | 182 140 110 |

140-5.6" 150-6.0" | +4 -3 | 11278 13871 | 88 72 |

High Chrome Grinding Media Balls

Our grinding ball:

1)Dia.:17~150mm, 2)High Hardness &Low Breakage, 3)Good wear-Resistance, 4)High Cr balls Hardness:58HRC Min.

Our main products:

High& low chrome cast grinding balls

High& low chrome alloyed casting Cylpebs

High& low chrome alloyed micro-balls

Forged Grinding balls

A) Diameter: 20~150mm

B). Hardness

High Cr : Surface HRC >58

Middle Cr:Surface HRC>47

Low Cr : Surface HRC >45

Forged ball: HRC 55~67

C). Characteristics:

1) High hardness

2) Good wear Resistance

3) No breakage

4)Even wearing

D). Applied fields:

1) Metal Mines

2) Cement plants

3) Power stations

4) Chemical industry

E).Chemical Composition.

High Cr : C:2.0~3.2,Si≤1.0, Mn≤1.5, Cr: 10~28, Mo ≤1.0, P≤0.10, S≤0.08.

Middle Cr.:C:2.1-3.2;Si0.5-2.2;Mn0.5-2.0 Cr 6-10; Mo1-1.0; Cu0-0.8; Ni0-1.5; P<0.10 S<0.006

Low Cr: C:2.0~3.0,Si≤1.2,Mn≤1.5, Cr: 1.0~2.2, Mo ≤1.0, P≤0.10, S≤0.10.

Forged balls: C:0.53~0.74,Si:0.15~0.37, Mn:0.45~1.2,S:0.04max. P:0.04Max.Cr :0.60max.

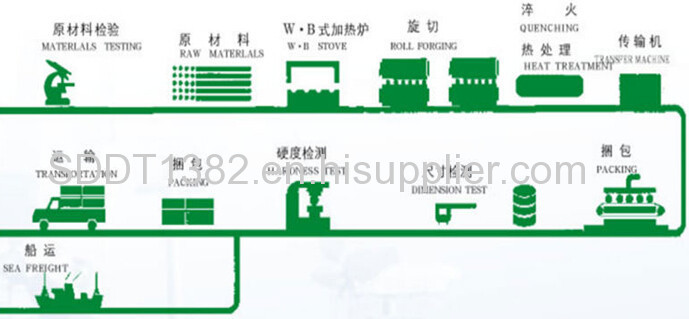

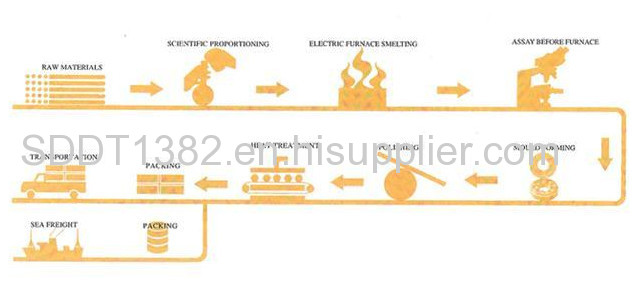

The Process Line of Production:

WORKSHOP:

Testing Equipment and Certification:

Company Information:

1.Professional Grinding balls Manufactoryfounded in 1981;

2.Advanced production equipment;

3.Exported more than 20 countries;

4.Experienced developmentpersonnel,professional designers,salesman and skilled workers

5.Capacity:10,000mt/month.

Our Services:

1.Free sample for your test before orders;

2.Soonest delivery time ;

3.Cooperate with many famours shipping companies,and sent the goods to your port in time;

4. Any feedback after sales would get our soonest reply.

Contact: